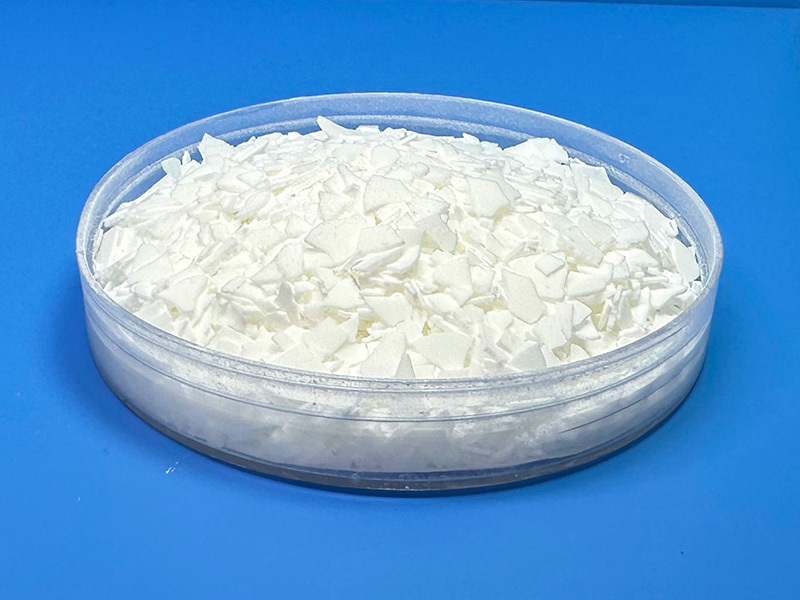

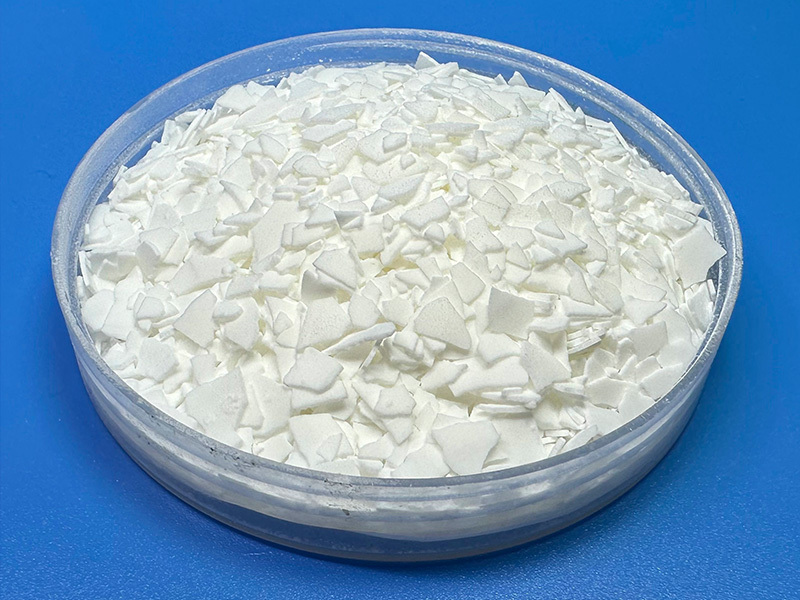

13X Molecular Sieves

13X Molecular sieve , also called zeolite 13X , is one type of aluminosilicate crystal with average pores measuring of 9 angstrom (0.9 nm). Molecular with kinetic diameter smaller than 9 angstrom will be adsorbed by zeolite 13X, otherwise be excluded.

Key words:

Categories:

Detail

Product Introduction:

13X Molecular sieve , also called zeolite 13X , is one type of aluminosilicate crystal with average pores measuring of 9 angstrom (0.9 nm). Molecular with kinetic diameter smaller than 9 angstrom will be adsorbed by zeolite 13X, otherwise be excluded.

13X Molecular Sieve is a large-Pore and high-capacity adsorbents which is widely used in cryopumping, drying of cracked gas, air separation, natural gas Processing, Petrochemical industry and catalysis of hydrocarbon Processing and air separation.

Zeolite 13X molecular sieves are typically used for removal of carbon dioxide and moisture from air, mercaptan and hydrogen sulphide from hydrocarbons such as LPG, butane, propane, etc

13X molecular sieve for air separation, mainly composed of aluminosilicate, with a pore size of 10A. It is a special molecular sieve produced to meet the special requirements of the cryogenic air separation industry, further improve the adsorption capacity of molecular sieve for CO2 and H2O, and avoid the phenomenon of freezing tower in the air separation process.

13X molecular sieve for air separation has high carbon dioxide adsorption capacity, and it also has the characteristics of fast adsorption speed, low regeneration temperature and long service life for trace water in the air, acetylene and gaseous hydrocarbons. This product is applicable to various large cryogenic and PSA air separation devices.

Specifications for molecular sieve used for air separation:

|

Items |

Unit |

Sphere |

Sphere |

Pellets |

Pellets |

|

Diameter |

(mm) |

1.6-2.5 |

3.0-5.0 |

1/16” |

1/8” |

|

Static H2O adsorption (%) |

(%) |

≥26.0 |

≥26.0 |

≥26.0 |

≥26.0 |

|

Static CO2 adsorption (%) |

(%) |

≥18.5 |

≥18.5 |

≥18.5 |

≥18.5 |

|

Bulk density |

g/ml |

≥0.62 |

≥0.62 |

≥0.62 |

≥0.62 |

|

Loss on ignition |

(%) |

≤1.50 |

≤1.50 |

≤1.50 |

≤1.50 |

|

Wear ratio |

(%) |

≤0.10 |

≤0.10 |

≤0.20 |

≤0.20 |

|

Crushing strength |

(N) |

≥30 |

≥80 |

≥30 |

≥75 |

|

Size ratio up to grade |

(%) |

≥98 |

≥98 |

≥98 |

≥98 |

Package:

15KG steel drum, inner 0.8mm plastic bag, shape: Φ270mm×380mm

25KG carton barrel, inner 0.8mm plastic bag shape: Φ320mm×480mm

135KG sealed steel drum, inner baking paint, shape: Φ595mm×860mm

Attention:

To avoid damp and pre-adsorption of organic before running, or must to be reactivated.

Related products

Product inquiry

Copyright © Puyang Tiancheng Chemical Co.,Ltd.

This website already supports IPV6 Powered by 300.cn

Online message