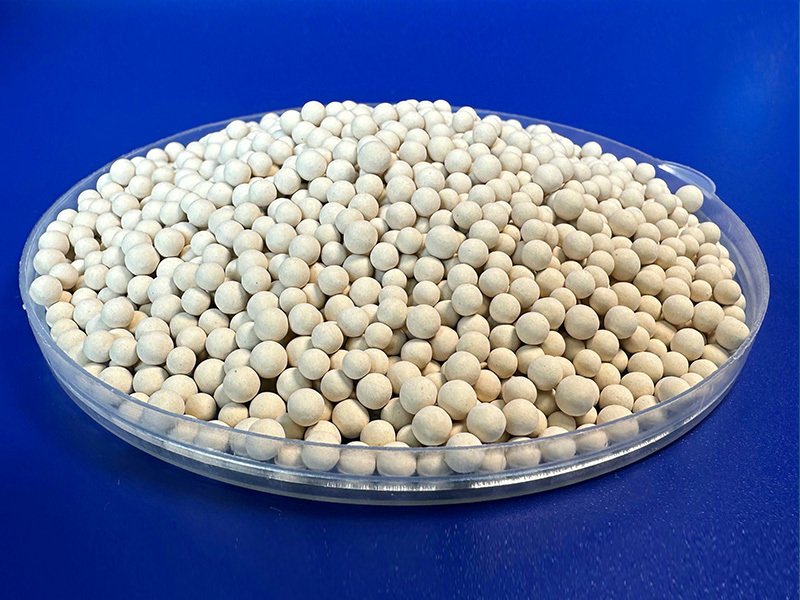

3A Molecular Sieves

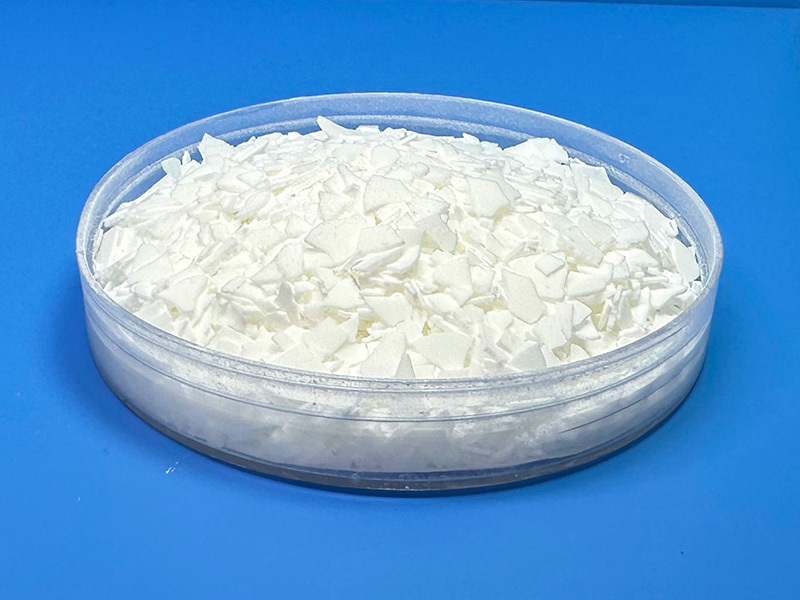

3A molecular sieve,sometimes also known as 3A zeolite molecular sieve,is a kind of potassium-sodium aluminosilicate with LTA-type skeleton structure which is composed of silicon-oxygen and aluminum-oxygen tetrahedrons.The main crystal hole of the 3A molecular sieve is an eight-membered ring structure, and the crystal pore size is 3Å (0.3nm).This kind of Molecular Sieve is mainly used to adsorb water, and does not adsorb any molecule with a diameter larger than 3A. According to the characteristics of industrial applications, the molecular sieve 3A produced by Fulong has faster adsorption speed, more regeneration times, higher crushing strength and stronger wear resistance,which greatly improves the utilization efficiency of molecular sieves and prolongs the service life of molecular sieves. It is the first choice desiccant necessary for deep drying,refining and polymerization of gas and liquid phases in petroleum and chemical industries.3A molecular sieves are usually used in ethylene, propylene, butadiene, methanol, ethanol, natural gas, cracked gas, refrigerant dehydration, etc.

Key words:

Categories:

Detail

Introduction:

3A molecular sieve,sometimes also known as 3A zeolite molecular sieve,is a kind of potassium-sodium aluminosilicate with LTA-type skeleton structure which is composed of silicon-oxygen and aluminum-oxygen tetrahedrons.The main crystal hole of the 3A molecular sieve is an eight-membered ring structure, and the crystal pore size is 3Å (0.3nm).This kind of Molecular Sieve is mainly used to adsorb water, and does not adsorb any molecule with a diameter larger than 3A. According to the characteristics of industrial applications, the molecular sieve 3A produced by Fulong has faster adsorption speed, more regeneration times, higher crushing strength and stronger wear resistance,which greatly improves the utilization efficiency of molecular sieves and prolongs the service life of molecular sieves. It is the first choice desiccant necessary for deep drying,refining and polymerization of gas and liquid phases in petroleum and chemical industries.3A molecular sieves are usually used in ethylene, propylene, butadiene, methanol, ethanol, natural gas, cracked gas, refrigerant dehydration, etc.

Technical Parameter for 3A Molecular Sieves

| Shape | Spherical | Pellets | ||

| Model | 3AMS-B1 | 3AMS-B2 | 3AMS-P1 | 3AMS-P2 |

| Diameter (mm) | 1.6-2.5mm | 3.0-5.0mm | 1.6 mm | 3.2mm |

| Size ratio up to grade (%) | 98 min | 98.0 min | 98.0 min | 98.0 min |

| Bulk density (g/ml) | 0.65 min | 0.65 min | 0.60 min | 0.60 min |

| Crushing strength (N) | 30 min | 80 min | 30 min | 70 min |

| Wear ratio (%) | 0.40 max | 0.40 max | 0.40 max | 0.40 max |

| Static H2O adsorption (%) | 20 min | 20 min | 20 min | 20 min |

| Ethylene adsorption (‰) | 3.0 max | 3.0 max | 3.0 max | 3.0 max |

| Water content (%) | 1.5 max | 1.5 max | 1.5 max | 1.5 max |

| Dynamic vapour absorption | 10 min | 10 min | 10 min | 10 min |

Recommend applications:

1. Dehydration of unsaturated carbohydrates (such as ethylene, propylene, butadiene).

2. Absorption of carbohydrates in natural gas and production of natural gas with minimum COS value.

3. Dehydration of methanol, ethanol and other polar compounds.

Regeneration:

1. Removal of water vapor: The product can be regenerated by heating. The temperature of the inlet gas passing through the molecular sieve bed should be kept at 200-350℃, the pressure 0.3-0.5kg/cm2, and the temperature of the outlet gas should be 150-180℃.

2. Removal of organic gases: First, remove the organic matter adsorbed in the molecular sieve, and then remove the adsorbed water according to the above method.

Package:

Net 150KG/160KG galvanized metal drum.

Net 25KG carton box lined with aluminum foilg bag.

Net 140KG/160KG fiber drum.

Net 1000KG container bag or other packings.

Related products

Product inquiry

Copyright © Puyang Tiancheng Chemical Co.,Ltd.

This website already supports IPV6 Powered by 300.cn

Online message