DCPD Petroleum Resin

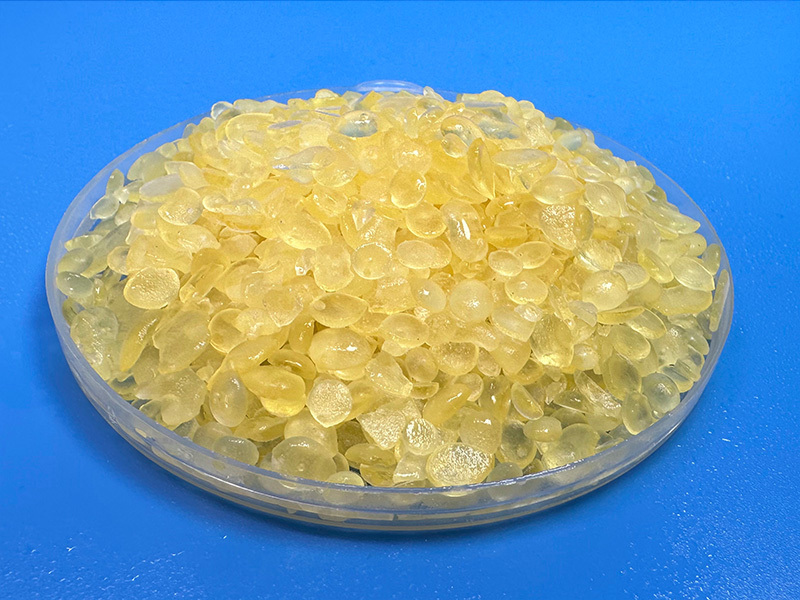

Hydrocarbon DCPD Resins with the grades of HCR-D100T and HCR-D238C are also known as DCPD Petroleum Resins.They are pale yellow thermoplastic resins obtained from mainly polymerizing dicyclopentadiene,unsaturated aliphatic 1,3-pentadiene (1,3-piperlene) and some monomers derived from the process of thermal cracking of naphtha.

Key words:

Categories:

Detail

Introduction:

Hydrocarbon DCPD Resins with the grades of HCR-D100T and HCR-D238C are also known as DCPD Petroleum Resins.They are pale yellow thermoplastic resins obtained from mainly polymerizing dicyclopentadiene,unsaturated aliphatic 1,3-pentadiene (1,3-piperlene) and some monomers derived from the process of thermal cracking of naphtha.

Characters:

Light color

Low viscosity

Good bond strength

Low volatility

Low molecular weight

High transparency

Distinguished initial adhesion

Excellent compatibility with polymers

Good price advantage

Specification:

|

Items |

HCR-D100T |

HCR-D238C |

|

Appearance (eyeballing) |

yellowish granule |

yellowish granule |

|

Softening Point (R&B)℃ |

100-105 |

108-118 |

|

Color No. (50% Toluene)Ga. |

3.0-5.0 |

5.0-8.0 |

|

Acid Value(mgKOH/g) |

0.50 max |

0.50 max |

|

Ash Content(wt%) |

0.10 max |

0.10 max |

|

Melt Viscosity(200℃)mPa.s |

250 max |

300 max |

|

Bromine Value (gBR/100g) |

100 max |

185 max |

Applications:

The major usages of the DCPD Hydrocarbon Resins are the binder for rubber and tire compounding, strap, shoes and Concrete Cure Compounding,etc.

Package:

Net 25kgs paper Kraft bag or PP woven-plastic bag.

Storage:

DCPD Hydrocarbon resin is non-hazardous product, stored in dry and cool place with fire fighting facilities, far away from fire, sunshine, moisture and pollution.

Related products

Product inquiry

Copyright © Puyang Tiancheng Chemical Co.,Ltd.

This website already supports IPV6 Powered by 300.cn

Online message